Reducing the energy consumption of stirring devices in biogas digesters by numerical flow simulations

The aim of this work was to find possibilities to reduce the energy consumption of paddle stirrers used in biogas digesters. Two different stirrer types were investigated by using numerical simulations, one with a vertical axis the other one with a horizontal axis. Additionally, two different viscosities were applied to the simulations.

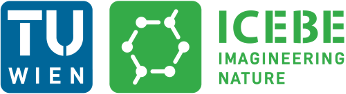

Model of BGP Strem

The slurries in biogas digesters have a non-Newtonian behaviour - so the rheological properties of the slurries used in the simulations had to be determined first. For optimization the rotation frequency of the stirrers was varied in the simulations, and the steady-state flow field, the resulting torque, and the average velocities were analyzed. This should ensure that the distribution of the substrates in the digesters is not negatively influenced by reducing the speed of the stirrers. As a result of the simulations the performance curve of the digesters could be calculated with the dimensionless Newton- and Reynolds-number. With this approach a generalized correlation between the flow field and the energy consumption was established and possibilities for energy savings could be revealed. Results show in both cases a potential of about 50% of energy saving by optimized operation of the stirring devices.

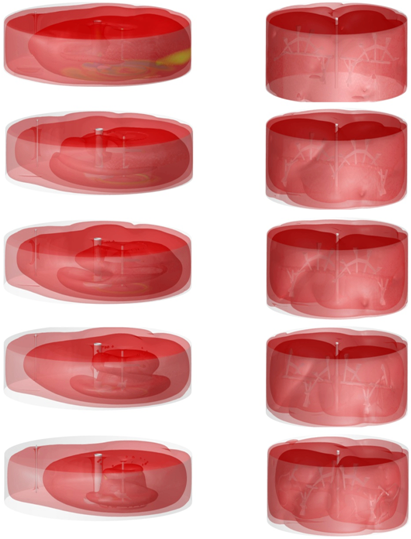

Velocity in the digesters with decreasing rotation number, left column Plant A from 15 down to 4rpm, right column Plant B from 7 down to 2rpm