Improvement of small-scale log wood stoves by experimental investigation combined with Computational Fluid Dynamics

In this work, a comprehensive model covering the heterogeneous process of beech log wood combustion was developed. The model was validated by carrying out extensive experimental work. Different setups of the combustion air injection were investigated. By analyzing the CFD-results, an enhanced air distribution system was designed and tested in a pilot stove. This new configuration provides a more evenly distributed combustion air insertion, leading to rigorous reduction of deposit formation on the glass surface.

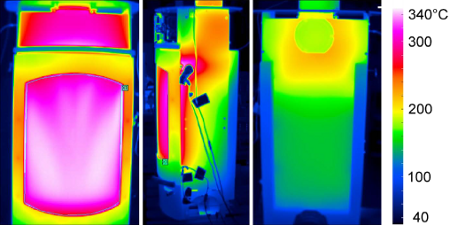

Thermographic measurement of the stove's outer surface temperature (emission factor corrected for steel and glass surfaces)