Design, calibration and numerical investigation of a macro viscosimeter

The aim of this work was the identification of the rheological behaviour of typical slurries used in biogas digesters. Subsequently the results were used to simulate the mixing behaviour of biogas digesters. These slurries contain a large amount of organic and inorganic particles (up to 12%) with particle sizes and fibre lengths varying in a large range which leads to difficulties during the measurement. The idea was to design a new type of viscosimeter which allows to measure the properties of such slurries. It is called macro-viscosimeter because the volume from usually 30-50mL was increased to more than 10L in the same manner the gap width was also increased and the rotating cylinder was replaced by a vane stirrer to assure a homogenous mixture during the measurement.

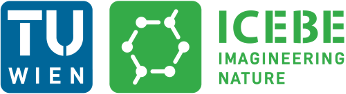

This figure shows a digester with 3 large paddle stirrers, which have a diameter of about 6.5m and a length of 12m. The model has 3.9mio cells and shows the flow field at a real time of 7s. A time step size of 0.0015s was used. The simulation time was 7 days on the ICP5 cluster at TU Vienna.

This apparatus was calibrated with different methods, the Metzner-Otto-Method, a numerical approach and with theoretical methods. The results point out that the Metzner-Otto-Method fails to produce reliable results for the shear rate distribution while the numerical results shows slightly higher torques. It was shown that the calibration with a combination of all methods can be done successfully.

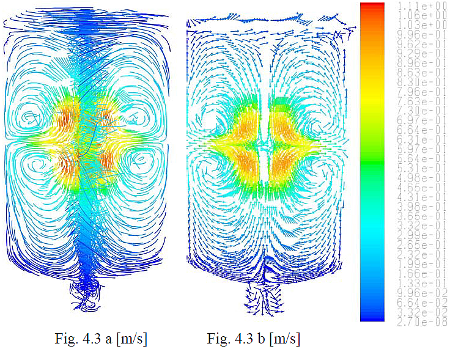

Picture 4.3 a and b offer a view of the vortices and velocity vectors within the vessel in a steady state condition (simulated real time 10s).