CFD Analysis of Injection of Heavy Fuel Oil and Plastic Particles into a Blast Furnace Raceway – Estimation of Droplet Size Distribution

CFD methods have been used to simulate the injection of plastics into the blast furnace raceway at blast furnace A at voestalpine Stahl GmbH, Linz (Austria). Various auxiliary reducing agents like oil, tar, pulverized coal, natural gas, coke oven gas and waste plastics are applied for injection into the blast furnace to decrease the coke rate. For a better understanding of the effects of combined injection an extended model is being developed based on the CFD model for plastic particle injection reported earlier

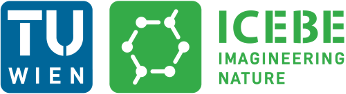

Detailed blast furnace geometry – simulated section in the lower part of the furnace featuring three of 32 tuyéres and also includes the hot blast pipes.

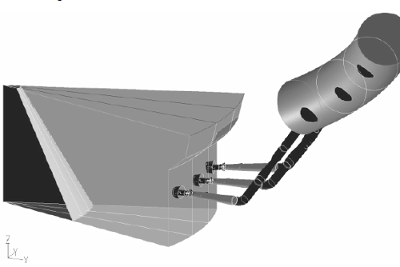

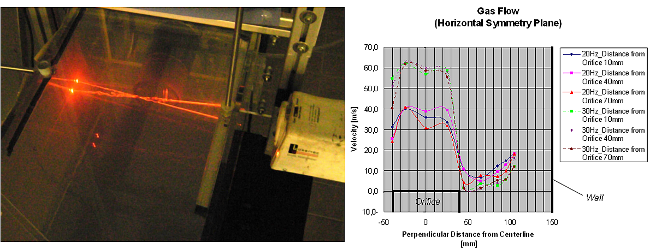

The new model makes use of the capability to predict the raceway shape based on a new porous media approach avoiding the high computational effort of a full eulerian multiphase formulation and incorporates also a simplified reaction mechanism for calculation of the high temperature conversion of the injected materials. In addition to that code to handle the injection of multicomponent droplets like heavy fuel oil and tar has been incorporated. An important parameter to give valid estimates of the oil spray length is the droplet size distribution of the fuel oil. Unfortunately for the injection lance geometry used at the modelled blast furnace no suitable correlations to predict the spray parameters like droplet size and droplet speed have been found. Since direct measurements of the size distribution at raceway conditions are not possible a lab scale model based on similarity scaling rules (Reynolds analogy) has been developed. Optical measurements using particle image velocimetry (PIV), laser doppler anemometry (LDA) and a high speed camera have been carried out.

Gas Flow Velocity by Laser Doppler Velocimetry (LDV)

Based on this experimental data a correlation for the spray parameters has been implemented into the CFD model. Furthermore measurements of other high temperature material properties have been carried out, e.g. for the thermal conductivity of the coke bed. Using these improved boundary and inlet conditions as well as improved physical properties the quality of the CFD simulation results and the predictions could be further improved.