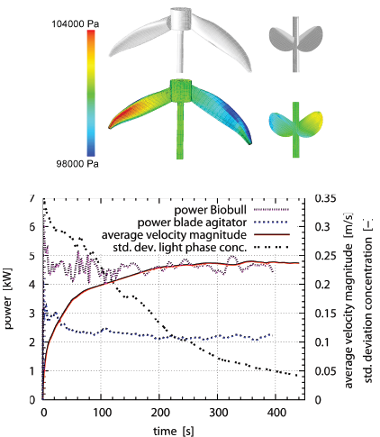

Scale-Up of Biogas Plants by Investigation of the Mixing Process using Computational Fluid Dynamics

In the presented work the mixing behavior and performance of the agitation system in biogas plants was studied to support the scale-up process by carrying out Computational Fluid Dynamic (CFD) analysis. The fermentation medium was implemented using an Euler-Euler multiphase approach. The description of specific material properties was achieved by implementing user-defined subroutines. CFD proved to be a very useful tool for this type of problem definitions. The results of the research work were successfully put into practice: the first facility in scale-up dimensions is already in operation, reducing the CO2-emissions by the production of biogas.

Evolution of average velocity magnitude, power uptake and mixing characteristics in time

CFD can be used to model and predict the actual fluid dynamics in a closed system. Thus it may help to plan optimal reactor geometries, positions and combinations of agitation systems as well as to minimize the energy requirements. Following this strategy, the energy efficiency of such facilities can be increased, reducing the net emission of greenhouse active CO2.