Design, construction and calibration of a macro-viscosimeter using CFD-methods

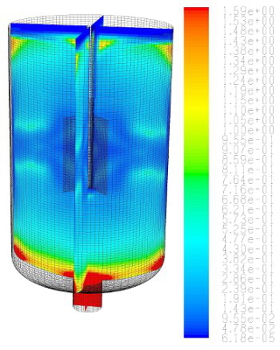

To optimize the power input, the mixing behaviour and the geometry in biogas fermenter it is necessary to determine the rheological behaviour of the used slurry. These slurrys contain a large amount of suspended particles and fibres. Thus this fluid has a complex rheological attribute and the used viscosimeter has to deal with this challenge.

Precisely because this design was complety new an was never used bevor a calibration has to be carried out. This is done with the so called Metzner-Otto-Method. Additional the calibration was also done with CFD Methods using user defines subroutines.

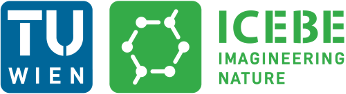

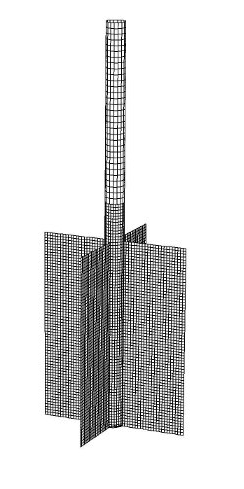

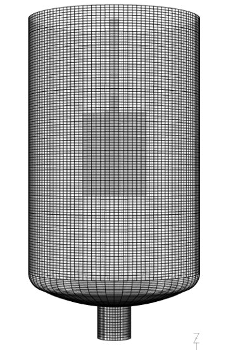

Picture 1 und 2: left side, mesh of the stirrer and the vessel, Picture 3: middle, vector-plot of the velocity field in the vessel at 250 rpm and non-Newtonian behaviour, Picture 4: right side, local depended viscosity in the vessel